Product Name:?V Model Mixer

Purpose:?Apply to mix powder and granular material used in pharmaceutics, chemicals, food, metallurgy industry.

Features: This machine possesses all the advantages of equivalent products in home and abroad. Inequilateral tube provide sufficient mixing of material, vacuum automatic material feed in and seal butterfly valve discharge realize dustfree operation and ideal result of mixing. Tube body is made of stainless steel and polished inside and outside, clean and widely used. Equipped with self-stop device, this machine boasts delicate construction and good appearance.

Main Technique Parameter:

| Model | VH-0.5 | VH-0.5 | VH-0.5 | VH-0.5 | VH-0.5 | VH-0.5 |

| Volume(m3) | 0.5 | 1.0 | 1.5 | 2 | 2.5 | 3 |

| Feed Coefficient | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Turning Height(mm) | 2455 | 2700 | 2933 | 3200 | 3800 | 4015 |

| Tube Body Rotation Speed(r/min) | 15 | 12 | 10 | 10 | 10 | 10 |

| Power(Kw) | 1.5 | 3 | 4 | 5.5 | 7.5 | 7.5 |

| Weight(kg) | 550 | 850 | 980 | 1400 | 1600 | 1800 |

| Outline Dimension(m)(L*W*H) | 2.5×1.2 | 2.95×1.4 | 3×1.6 | 3.5×1.8 | 4×1.95 | 4×2 |

晶罐-300x196.jpg)

Product Name:PZG-series reactor

Purpose:The epuipment can be applicable to dispense and store liquid material of industries such as chinese traditional medicine, foodstuff,chemical industry.Put steam or cool water into the jacket to keep the material in the premillm temperature.The German-imported agitator can avoid the material spray rich ratio and lean ratio of injection,big infusion.it has the advantages of high dfficiency and ease of operation,there is automatic rolling sprikler equipped in the container to make sure it is cleaned thoroughly.it adopts sus304 or316stainless steel and does mirror polishing.it qualifies GMP standard.

Main Technique Parameter:

| model items | PZG-1000 | PZG-2000 | PZG-3000 | PZG-4000 | PZG-5000 | PZG-6000 | PZG-10000 |

| volume(L) | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 10000 |

| pressure in interlayer(MPa) | 0.09 | ||||||

| pressure in jacket(MPa) | 0.09 | ||||||

| motor power(kw) | 1.1 | 2.2 | 2.2 | 3 | 3 | 3 | 5.5 |

| condenser area(m3) | 4 | 5 | 6.5 | 8 | 10 | 12 | 18 |

| speed of agitator(rpm) | 20-100 | ||||||

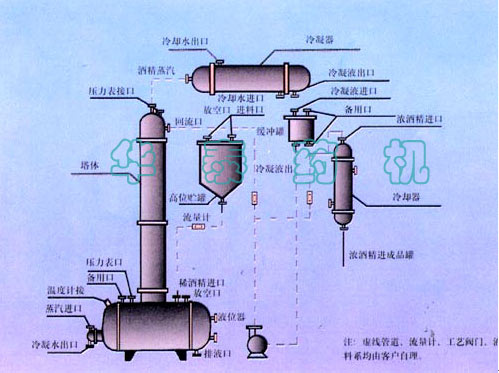

Product Name:JS series high effect alcohol distilling tower

Purpose:?This equipment adopts high efficient stainless steel corrugated fillings,all made of stainless steel in order to ensure the alcohol can’t be polluted.The tower adopts knock-down V style pipe,so it is convenient for heating ektexine and cleaning the wall wiall of the tower.The equipment adopts two styles of external and internal heating,the clients may choose it according to the pratical needs.

Main Technique Parameter:

|

Model items |

JS-200 | JS-300 | JS-400 | JS-500 | JS-600 | JS-800 |

| Volume (L) | 900 | 1100 | 1600 | 2000 | 2500 | 3200 |

| Recycle capacity(kg/h) | 45-60 | 90-100 | 150-160 | 280-300 | 420-450 | 600-630 |

| Condenser area(m2) | 4.0 | 9 | 16 | 25 | 36 | 56 |

| Condenser area(m2) | 1 | 1.6 | 3 | 3 | 3 | 4.5 |

| Recycle density | >90% | |||||

| Steam pressure(MPa) | 0.1 | |||||

| Weight(kg) | 900 | 1500 | 2350 | 3400 | 4500 | 6800 |

| Height (m) | 9.5 | 11.1 | 11.7 | 12.6 | 12.6 | 13.8 |

| Dimension (m) | 2.9×1.55 ×9.5 |

3.3×1.64 ×11.1 |

4.59×1.85 ×11.7 |

4.8×2.15 ×12.6 |

5×2.2 ×12.6 |

5.5×2.0 ×13.8 |

Product Name:?Double-cone Turning Vacuum Dryer

Purpose:?This dryer is used to concentrate, mix and dry powder, granular, fiber and low temperature drying material (such as thick material with high sugar content and viscosity) using in the chemical, pharmaceutical and food industry. Particularly apply to oxidative, volatile, heat sensitive material and Chinese medical material granular.

Features:?Heat is transferred to material through heat source (hot water, steam or gasoline) passing inner housing in enclosed interlayer.

Drive by power, tank rotate slowly to facilitate the material mixing in tank in order to realize renew surface and advance drying effect.

Material are in vacuum state in tank, water content (solvent) at material surface reach saturation to vaporize and discharge out of tank by vacuum pump. Water content (solvent) in material continuously infiltrate and vaporize to surface and discharge, which could dry the material in very short time.

Exclusively sealed by mechanical seal to avoid overflow, leakage, dropping and made it unnecessary to change or repair packing regularly, meeting GMP requirements. This dryer has insulation layer design. Inner and outer material is made of 1CR18Ni9Ti for convenient manufacturing and cleaning.

Main Technique Parameter:

| Model Parameter | 30 | 350 | 500 | 750 | 1000 | 1500 |

| Design Volume(L) | 30 | 350 | 500 | 750 | 1000 | 1500 |

| Heating Area(m2) | 0.5 | 2 | 2.2 | 2.4 | 2.6 | 3 |

| Turning Number(r/min) | 16 | 12 | 12 | 10 | 10 | 10 |

| Vacuum Degree(MPa) | 0.075 | 0.075 | 0.075 | 0.075 | 0.075 | 0.075 |

| Weight(Kg) | 200 | 2000 | 2300 | 2500 | 2700 | 3100 |

Product Name:?Spray Dryer

Purpose:?Quick drying speed. Superficial area of material liquid is greatly enlarged after centrifugal spray. In high temperature airflow, 95-98% water content could be evaporated instantly to finish the drying process in few seconds.

Heat sensitive material is applicable. Liquid droplet and sirocco flow together in same direction. Due to this, although the temperature of sirocco is relatively high, material will not become too hot during evaporation. Temperature distribution in drying column is as following drawing:

Widely used. Applicable for numbers of material with large characteristic difference, such as resin of polymer; herbicide weed killer, vermifuge; carbohydrate; dairy etc.

This product could maintain fine grain with excellent dispersity, fluidity and dissolution ability due to instant drying.

Features:?Simple production process and convenient operation and control are the features of this equipment. Solvent with moisture of 40-60%(90% for special material) could be dried into powder products at one time and render crushing and screening unnecessary. It reduces production procedures, also is convenient to change operation condition to adjust, control or manage the production.

Main Technique Parameter:

| Item\Model | QZR | |||||

| 5 | 25 | 50 | 100 | 150 | 200 | |

| Inlet Temperature(℃) | ≤350 | |||||

| Outlet Temperature(℃) | <80~90 | |||||

| Water content maximum evaporation amount(Kg) | 5 | 25 | 50 | 100 | 150 | 200~2000 |

| Centrifugal Spray Head Driving style |

Compressed air movement | Mechanical movement | ||||

| Rotation Speed(r.p.m) | 25000 | 22000 | 21500 | 18000 | 18000 | 15000 |

| Spray Disc Diameter(mm) | 50 | 102 | 108 | 108 | 150 | 180~340 |

| Heat Source | electric | electric | electric+steam | electric+steam | electric+steam | decided by user |

| Max power of Electrical heating(Kw) |

8 | 31.5 | 60 | 81 | 99 | |

| Outline Dimension(m) | 1.8?.93 ?.2 |

3?.7 ?.26 |

3.7?.2 ?.1 |

4.6?.2 ? |

5.5?.5 ? |

|

| Dried Powder Recycle | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

管真空減壓濃縮器-300x175.jpg)

Product Name:?Coil Vacuum Concentration Pot

Purpose:?This widely used and high concentration efficiency equipment is applied to heat sensitive material concentration (such as Chinese & Western Medicine, diary etc.).

Features:?This equipment is a columnar tank with insulation jacket. The upper and lower part of equipment are connected with flange for the purpose of repair, installation and lifting. Internal heating coil is composed by three to five rows oblate stainless steel rings. Steam is to be heated in coil. Manhole and lamp opening are equipped with recycle condenser at upper part of evaporator to recycle alcohol (organic dissolvent).

Main Technique Parameter:

| Type | PRB-300 | PRB-700 | PRB-1000 |

| Evaporation Capacity(Kg/h) | 300 | 700 | 1000 |

| Heating Coil Pressure(MPa) | 0.02-0.05 | ||

| Used Vacuum Degree(MPa) | 0.08 | ||

| Heating Area(m2) | 3.7 | 8 | 11 |

| Steam Consumption(Kg/h) | 330 | 770 | 1100 |

| Water Consumption(t/h) | 12 | 20 | 30 |

Product Name:SJN3 series three energy saving concentrator

Purpose:The equipment is used in chinese traditional medicine,western medicine,glucose,starch,MSG,dairy products and chemist to conce ntrate their liquid,especially suitable for termally sensitive materials to concentrate.

Features:Combining the advantages of domastic homogeneous products and clients suggestion, our company improved the design aboratively,and the effectiveness is much better.

1.Adopts the form of making output heat circulation system and vacuum negative evaporation combining together to fasten the speed. Concentrating gravity can reach 1.25.

2.The liquid is concentrated in sealing and without foam condition. The materials flowed out have no pollution, the taste of the medicine is very heavy, the cream is made evenly.

3.With adoption of three-efficient simultaneouse evaporation, three-time repeatde usage of vapour, the concentrator saveenergy consumption, which is reduced 70% compared with single-ef ficient one.

4.The solvent recovery device can be designed according to the clients?special requirmet. Three different medical liquids can be concentrated simultaneously. Concentrating three different medicinal liquid, one-efficient, double-efficient, three-efficient can recovery the cream in many times. The material can be added contiunously.

5.The parts contacts with materials is made of stainless steel and reaches GMP standard.The surface of insulating layersof heater and evaporator is made of stainless steel, which makes its feature good-looking and deluxe.

6.This equipments can automatically drain, alleviate to labor the strength, and have the half automation the function.

Main Technique Parameter:

| Model Items | SJN3-500 | SJN3-1000 | SJN3-1500 | SJN3-2000 | SJN3-3000 |

| Evaporation capacity(kg/h) | 500 | 1000 | 1500 | 2000 | 3000 |

| Cost steam(kg/h) | 400 | 700 | 1100 | 1400 | 2200 |

| Steam pressure(Mpa) | <0.1Mpa | ||||

| Dimension(m)L*W*H | 5.3*1*3.4 | 7.0*1.5*4.0 | 7.5*1.5*4.0 | 7.9*1.8*4.0 | 8.5*2*4.3 |

| Cost water(T/H) | 9 | 18 | 27 | 36 | 60 |

Product Name:WZ-series external circulation concentrator

Purpose:The equipment is widely used in liquid material concentrating of medicine,chemical industry and foodstuff as recovery of organic solvent Especially suitable for thermal sentitive materials such as alcohol extracting liquid,antibioticzymotic liquid,fermentation liquid, fruit juice and milk under vacuum condition making low temperature continuous concentration.It has much better effectiveness in various and small quantity materials.

Features:

1.Alcohol recycling:strong recycling capacity,, adopt vacuum concentrating flow, the production rate has improved 5-10 times than the old types, reduced 30% of energy cost. It has the character that small investment but big profit.

2.concentrating materials: the equipmet adopts the style that combineing externall heating cycling and vacuum vaporizing. Vaporizing speed is very fast, concentrating gravity can reach to 1.3. The liquid materials are concentrated under the completely sealing condition and three is no foaming. The liquid concentrated by this equipment has the features that no pollution and strong flavor. And it is easy to clean(cleaning can be done as soon as opening the upper and lower covers).The machine is easy to operate, covers small areas, the heater and vaporizer adopt the stainless steel heat keeping structurre, the shell is made of stainless steel and the surface is mirror or matted process.

Main Technique Parameter:

| Model Items | WZ-300 | WZ-500 | WZ-1000 | WZ-2000 | WZ-3000 |

| Evaporation capacity(kg/h) | 300 | 500 | 1000 | 2000 | 3000 |

| Cost steam(kg/h) | 330 | 550 | 1100 | 2200 | 3300 |

| Steam pressure(Mpa) | <0.1Mpa | ||||

| Vacuum degree(Mpa) | 0.06~0.08 | ||||

| Heat area(m2) | 4.5 | 7 | 14 | 28 | 56 |

| Condenser area(m2) | 6 | 10 | 20 | 40 | 60 |

Purpose:?The unit is widely used for liquid material evaporating concentration and poultice making process in Chinese & Western Pharmacy, light chemical and food industry, especially applied to low temperature vacuum depressurizing concentration of? heat sensitive material, and extracturm of 1.4 specific gravity could be made according to this.

This equipment is a new product features in high efficiency, energy economizing, low consumption which is developed according to technical innovation and has been awarded national patent, patent No. 92218691.X.

Features:?Different as double effect and triple effect evaporating concentration for poultice making.

For normal double effect and triple effect evaporating concentrator, the final poultice is processing in bundle pipe heater. Due to high density and poor fluidity of material, furring is easily formed on pipe walls which is hard to clean and cause extracturm loss.

The preliminary stage of this equipment adopts high evaporating velocity and good despumation external cycling heating and positive pressure evaporating method. In bundle pipe heater, liquid material displayed as film rotation in evaporator. Water content is rapidly evaporated under the vacuum effect and foam is swept along the pipe walls to prevent material loss. Liquid material cycle naturally under expansion kinetic energy and gravity difference. When specific gravity approach 1.2, liquid material is totally sucked into final evaporator. Poultice making with lower jacket heating and agitating with wall scraper could effectively prevent dense extracturm coking at internal pipe walls.

There is A type and B type for this equipment. A type each effect evaporator are vertical barrel, agitating are classified as upper and lower type among which upper type final effect is small length to diameter ratio construction. B type final effect evaporator adopts ball shape upper agitator, lower heating jacket is installed at the bottom of all final effect. There are many advantages for this construction: shallow pot and large diameter enlarge the heating surface and liquid exposing surface to facilitate evaporation. Wall scraper agitating force liquid material to cycle and improve the heat conducting performance, prevent level surface from filming due to increasing viscosity, and thus reduce temperature difference loss, speed up secondary steam exhalation. So it enjoys more superiority in high concentration (specific gravity 1.4) poultice making and also favorable for relatively low concentration evaporating concentration.

The whole process of evaporating concentration poultice making is conducted under enclosed condition and no need for open pot to make poultice in an exposed way. Parts in contact with liquid material are made of high quality stainless steel, agitating seal shaft is mechanically sealed of our company production, which effectively prevent leakage and pollution. This seal complies with medicine and food hygiene requirements and GMP standard. Wear parts could be replaced and repaired according to customer’s demand in long-term at any time.

Quick opening cover is located on the top of heater and manhole to clean. On the upper part of evaporator there is an inlet cleaning ball.

Equipment enclosure is insulated with high smoothness stainless steel to reduce heat loss and save more energy. And also in favor of production safety and sanitation, and embody modernization of shop arrangement.

Main Technique Parameter:

Double effect technical parameter:

| ENS-400 | ENS-500 | ENS-700 | ENS-1000 | ENS-1500 | ||

| Total Volume(m3) | 1.98 | 2.5 | 3.15 | 4 | 7 | |

| Total Heating Area(m2) |

9.87 | 14 | 18 | 24 | 39.6 | |

| Evaporate Quantity(Kg) | 400 | 500 | 700 | 1000 | 1500 | |

| Steam Pressure(MPa) | 0.05~0.09 | |||||

| Evaporate Temperature(℃) |

One Effect | 80 | ||||

| Double Effect | 50 | |||||

| Vacuum Degree(Mpa) | One Effect | 0.055 | ||||

| Double Effect | 0.085 | |||||

| Steam consumption(Kg/h) | 230 | 280 | 380 | 530 | 800 | |

| Water Consumption Cycle (T/h) | 6 | 8 | 6 | 6 | 6 | |

| Outline Dimension(m) (L×W×h) |

3.8×1.3×3 | 4.3×1.4×3 | 5.0×1.5×3.5 | 5.6×1.5×4 | 5.7×1.8×4.5 | |

Triple effect Technical Parameter:

| SNS-500 | SNS-1000 | SNS-1500 | SNS-2000 | ||

| Evaporate Quantity(Kg) | 500 | 1000 | 1500 | 2000 | |

| Steam Pressure(MPa) | 0.05~0.09 | ||||

| Evaporate Temperature(℃) | One effect | 90 | |||

| Double Effect | 75 | ||||

| Triple effect | 60 | ||||

| Vacuum Degree(Mpa) | One Effect | 0.04 | |||

| Double Effect | 0.062 | ||||

| Triple effect | 0.085 | ||||

| Steam Consumption(Kg/h) | 200 | 400 | 600 | 800 | |

| Water Consumption Cycle(T/h) | 6 | 12.2 | 17 | 22 | |

| Outline Dimension(m) (L×W×h) | 5.5×1.4×3.3 | 8×1.5×4 | 9×1.7×4.1 | 9.5×1.9×4.2 | |

Product Name:TQ-series multi-functional extractor

Purpose:This The equipment is also suitable for chemical industry, foodstuff Bio-pharmaceuticals etc.

Features:

The equipment is suitable for extracting the effective composition of chinese traditional medicine including fragrant oil. It can be operated under the condition such as atmosphere. decompression pressruization, force circulation. hot reflux by the style such as water frying. warm soaking, percolation, and it also can recycle the organic solvent.

The equipment has four styes:positive cone oblique cone.straight cylinder and mushroon fashion.It not only can make stratic extracion but also can be served by different mixers to make paddle or riddle or ribbon dymatic extraction.The dymatic extraction will shortern the work time and improve output.

The equipment adopts advanced sealing system during processing and has been correspondence the GMP.It has been well accepted by clients both from home .

Main Technique Parameter:

| model Item | 0.5m3 | 1m3 | 2m3 | 3m3 | 4m3 | 6m3 | 8m3 | 10m3 |

| Volume(L) | 650 | 1200 | 2300 | 3300 | 4300 | 6400 | 8600 | 11000 |

| Pressure in pot(Mpa) | 0.09 | |||||||

| Pressure in jacket(Mpa) | <0.3 | |||||||

| Pressed air pressure(Mpa) | 0.6-0.7 | |||||||

| Diameter of inlet(mm) | 350 | 400 | 400 | 400 | 400 | 450 | 500 | 500 |

| Diameter of outlet(mm) | 600 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 |

| Heat area(m2) | 2.7 | 3.6 | 5 | 6.5 | 7.5 | 10 | 12 | 14 |

| Cool area(m2) | 3 | 4 | 5 | 8 | 6 | 8 | 12 | 15 |

| Condense area(m2) | 0.5 | 0.5 | 1 | 1 | 1 | 1.5 | 1.6 | 1.5 |

| Filter area(m2) | 0.25 | 0.25 | 0.25 | 0.25 | 0.35 | 0.5 | 0.5 | 0.8 |

| Mix rotate(r/min) | 25 | |||||||

| Mix power(kw) | 1.1 | 2.2 | 3 | 4 | 5.5 | 7.5 | 7.5 | 11 |